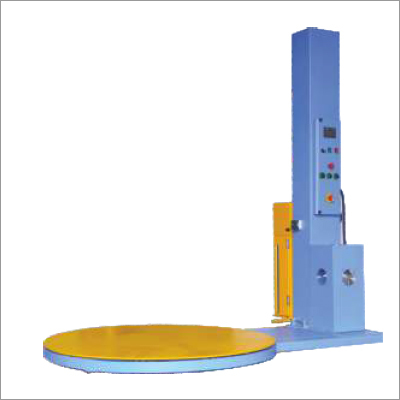

Heavy Duty Stretch Wrapping Machine

Heavy Duty Stretch Wrapping Machine Specification

- Product Type

- Stretch Wrapping Machine

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Semi-Automatic

- Color

- Sky Blue And Yellow

- Warranty

- Yes

Heavy Duty Stretch Wrapping Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque, Cash in Advance (CID), Cash Advance (CA)

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 2-3 Days

- Main Domestic Market

- All India

About Heavy Duty Stretch Wrapping Machine

Heavy Duty Stretch Wrapping Machine is used for packing loaded pallet by using stretch film. This equipment consists of hinged drive controlled film carriage and turntable with easy to adjust speed. Motor of this system is regulated by powerful motor for its smooth operation. Photoelectric cell of this machine is used for determining precise height of pallet. This machine uses electromagnetic brake for modifying tension of stretch film. We offer this machine both in non automatic and automatic operating mode based versions. Customers can obtain this machine in four different models. We are a prestigious manufacturer and supplier of best grade Stretch Wrapping Machine.

Heavy Duty Stretch Wrapping Machine Features:

- This machine uses polyurethane made stretch film as its packaging material.

- Film thickness ranges between 17 to 35 microns.

- This machine is available in different models having various dimensions.

- Equipped with safety limit switch, offered with pre-stretch system as optional feature to minimize film usage rate

- Film carriage is equipped with hinged drive for smooth vertical movement.

- Turntable equipped with hinged drive for stable turning during pallet loading.

- PLC control system for better functionality

- Inverter controlled motor speed for smooth and steady operation

- Two-dent turntable design for easy movability of machine

- Photoelectric cell to measure the pallet height

- Manual as well as auto operation mode

Heavy Duty Stretch Wrapping Machine Specifications:

Frequently Asked Questions:

1. What types of products can be wrapped using a stretch wrapping machine?

Ans: Boxes, bags, bottles, cans, and other products that are traditionally shipped on pallets can all be wrapped using a stretch wrapping machine. The device is applicable to a number of sectors, including the food & beverage, pharmaceutical, and manufacturing industries.

2. What are the benefits of using a stretch wrapping machine?

Ans: It a number of advantages, such as increased product stability during shipping, decreased product damage, improved packaging and shipping efficiency, and lower material costs.

3. What is the difference between manual and automatic stretch wrapping machines?

Ans: Manual stretch wrapping machines require an operator to apply the plastic film around the product or pallet. Automatic stretch wrapping machines use sensors and controls to apply the plastic film automatically. This results in a faster and more consistent wrapping process.

4. How do I choose the right stretch wrapping machine for my business?

Ans: When choosing a stretch wrapping machine, consider factors such as the size and weight of the products or pallets you need to wrap, the volume of products you need to wrap per day, the space available in your facility, and your budget.

5. What maintenance is required for a stretch wrapping machine?

Ans: Regular maintenance is essential to keep your stretch wrapping machine running smoothly. This includes cleaning the machine and its components regularly, checking for wear and tear on the parts, and replacing any worn or damaged parts. It's also important to follow the manufacturer's recommended maintenance schedule.

Price 225000 INR/ Unit

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1 Unit Per Week

- Delivery Time

- 2-3 Days

- Main Domestic Market

- All India

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Stretch Wrapping Machines Category

Economy Model Carton Stretch Wrapping Machine

Price 115000 INR / Unit

Minimum Order Quantity : 1 Unit

Product Type : Stretch Wrapping Machine

Automatic Grade : Automatic

Warranty : Yes

Material : Mild Steel

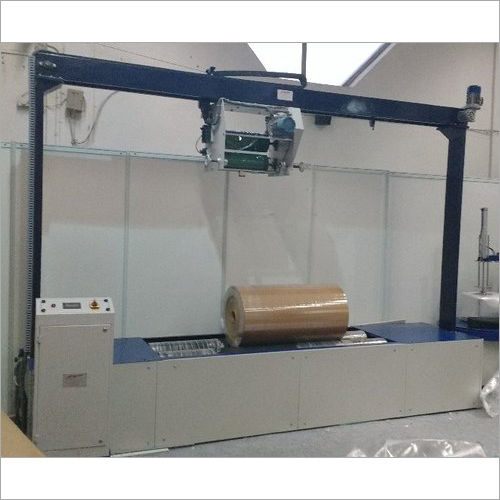

Paper Reel Packing Machine

Price 950000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Paper Reel Packing Machine

Automatic Grade : Automatic

Warranty : Yes

Material : Mild Steel

Reel Wrapping Machine

Price 950000 INR / Piece

Minimum Order Quantity : 1 Piece

Product Type : Reel Wrapping Machine

Automatic Grade : Automatic

JOY PACK (INDIA) Pvt. Ltd.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese